Carbon / Glass Fiber Composite Applications

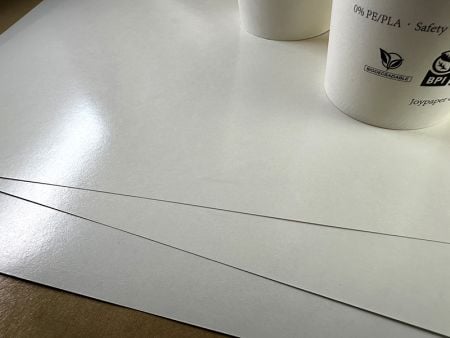

Release paper is a crucial auxiliary material in the production process of carbon fiber and glass fiber. One of its primary functions is to prevent resin from adhering to the mold, ensuring that the resin used in the process can be smoothly demolded after curing. Additionally, it serves as a protective layer, helping to reduce the risk of mechanical damage to carbon fiber and glass fiber during the process, thereby ensuring product integrity.

It's worth mentioning that JPC offers a variety of release papers for customers to choose from, covering various characteristics and application needs. Customers can select different types of release papers based on specific requirements, such as high-temperature resistance or adjustment of release force. Additionally, release papers can be paired with different printing options for easy differentiation of various processes or applications, such as distinguishing between different types of FAW.

Here are our recommended release papers commonly used in carbon fiber / glass fiber processes:

- Clay Coated Kraft Release Paper: High stiffness and high temperature resistance

- Double Side Coating PEK Release Paper: Excellent moisture resistance

- Single Side Coating PEK Release Paper: Can be cut into flat sheets

- Related Products

Single Side Coating CCK Release Paper

Single side coating CCK release paper is designed for improving production efficiency and reducing costs. So far, we have a wealth of customer case experiences...

DetailsDouble Side Coating CCK Release Paper

JPC offers double side coating CCK release paper with a basis weight ranging from 45g to 160g, and customizable release force from 10gf to 1200gf. We specialize...

DetailsSolvent free CCK Release Paper

Solvent free CCK release paper applies an environmentally friendly coating on high quality paper, either on one or both sides. Choosing solvent free products...

DetailsSolvent based CCK Release Paper

Solvent based CCK release paper is a type of paper that employs solvent coating on its surface. Currently, the top ten global manufacturers of tennis and badminton...

DetailsPrinting CCK Release Paper

Printing CCK release paper, using high quality CCK paper, is a type of release paper that employs flexographic printing technology to imprint desired text,...

Details